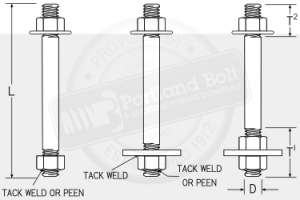

Thread Each End

The most common configurations for an anchor rod are either threaded on each end or fully threaded. Often times there is a nut either assembled or welded to the embedded end, a nut with a plate on top, or a nut on the top and bottom side of the plate. The plate sandwiched between two nuts design is frequently used to avoid welding to quenched and tempered anchor rods. This assists in creating a bearing surface that prohibits the rod from pulling out of the concrete. This is utilized with “cast-in-place” anchor rods, which are set prior to the concrete being poured.

- Nut Welded (optional)

- Nut & Plate Welded (optional)

- Two Nuts w/ Plate

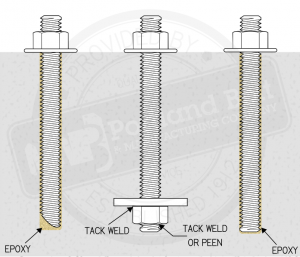

All Thread Rod

Fully threaded anchor rods are often times embedded without a bottom nut assembly by drilling a hole into an existing concrete foundation and using an epoxy, which will grip the threads and keep the rod from pulling out. If the rods are “cast-in-place”, they are set prior to the concrete pour and may utilize a nut and plate configuration similar to a rod with threads on each end.

- Nut Welded (optional)

- Nut & Plate Welded (optional)

- Two Nuts w/ Plate

- Epoxy Anchors (square and angle cut)

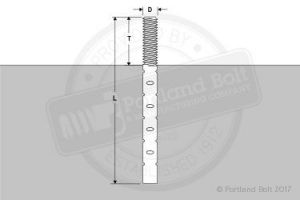

Headed Anchor Rod

Headed anchor bolts differ from anchor rods with threads on each end and fully threaded anchor rods due to only one of the ends being threaded and accepting a nut. The opposite end would be either a forged hex, heavy hex or square head. The forged head provides pull-out resistance, which can be increased with the use of a square or round anchor plate. The headed end is embedded into concrete foundations to secure light poles, bridge railing, structural steel columns, substation structures, etc.

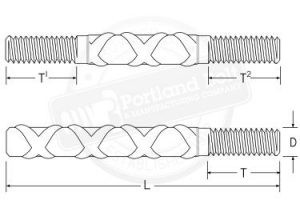

Swedged Rod

A swedged anchor rod is a design used in highway work, specifically in conjunction with bridge bearings. The threaded end projects from the concrete, while the embedded end possesses indentations that have been pressed into the round bar to provide pull-out resistance. The indentations are normally formed by pressing deformations into the rod and displacing the steel rather than machining steel away to form the dimples. Some departments of transportation are particular about the pattern and size of the indentations, so check your plans carefully when ordering swedged anchor rods.

Threaded Rebar

Threaded Rebar

Threaded rebar is used as an anchoring method when securing sign structures, wind towers, structural steel, and especially steel lattice transmission towers. To ensure proper thread fit the rebar must be turned down to remove the deformations. This uniform surface is used to create the required threads.

- A615 Grade 40, 60, 75, 80

- A706 Grade 60, 80