Anchor Rods

Anchor rods are threaded fasteners embedded in concrete foundations with the purpose of supporting light poles, traffic signal poles, structural steel columns, highway sign structures, steel towers, industrial equipment, and many other structures. Anchor rods can be cast-in-place or post-installed in an existing concrete slab. All anchor rods possess an element such as a nut, plate, nut with plate, forged head, epoxy with threaded rod, or swedging that anchors the rod in the concrete foundation. A threaded end projects from the concrete and is used with nuts and washers to anchor the structure to the foundation.

Anchor rods are threaded fasteners embedded in concrete foundations with the purpose of supporting light poles, traffic signal poles, structural steel columns, highway sign structures, steel towers, industrial equipment, and many other structures. Anchor rods can be cast-in-place or post-installed in an existing concrete slab. All anchor rods possess an element such as a nut, plate, nut with plate, forged head, epoxy with threaded rod, or swedging that anchors the rod in the concrete foundation. A threaded end projects from the concrete and is used with nuts and washers to anchor the structure to the foundation.

Anchor rods are also referred to as anchor bolts or foundation bolts. Anchor rods are readily available as stock items or manufactured to meet a variety of ASTM grades and configurations depending on the application.

This website only covers straight anchor rods with threads. For 90⁰ bent anchor bolts, please refer to www.portlandbolt.com.

Anchor Rod Specifications

There are a variety of ASTM specifications that apply to anchor rods. Although F1554 is the most commonly-used anchor rod grade, many other ASTM specifications can be used for anchor rods.

- ASTM F1554: ASTM specification designed exclusively for anchor bolts in which the grade identifies the minimum yield strength (ksi) of the anchor bolt.

- Grade 36: Mild steel anchor bolt with a minimum yield strength of 36 ksi.

- Grade 55: High-strength, low-alloy steel anchor bolt with a minimum yield strength of 55 ksi.

- Grade 105: High strength, quenched and tempered alloy steel anchor bolt with a minimum yield strength of 105 ksi.

- ASTM A307: Low carbon steel bolts typically manufactured from A36 or similar steel. The anchor rod version of this specification, Grade C, was eliminated in 2007.

- Grade A: Intended for general purpose applications which can include anchor rods.

- Grade B: Heavy hex bolts and fully threaded studs intended for cast iron flanges. However, some engineers specify A307 Grade B for use as anchor rods.

- Grade C*: This version of the A307 specification covering unheaded anchor bolts, either bent or straight, was eliminated in 2007 and replaced by F1554 Grade 36.

- ASTM A449: Medium carbon, quenched and tempered steel bolts used for general purpose applications, including anchor rods.

- ASTM A354: Medium carbon, alloy steel bolts that are quenched and tempered. Both grades are intended for general applications.

- Grade BC: Lower in strength than grade BD.

- Grade BD: Higher in strength than grade BC.

- ASTM A193: Alloy-steel and stainless steel bolts for high temperature or high-pressure service. Although sometimes specified as anchor rods, this grade of bolt is typically used for pressure vessels, valves, flanges, and fittings.

- Grade B7: Alloy steel that is quenched and tempered.

- Grade B8: Type 304 stainless steel.

- Grade B8M: Type 316 stainless steel.

- ASTM A320: Alloy-steel and stainless steel bolts for low-temperature service often specified for projects in Alaska, Canada, and other cold temperature environments.

- Grade L7: Alloy steel that is quenched and tempered and includes a Charpy impact test.

- Grade B8: Type 304 stainless steel.

- Grade B8M: Type 316 stainless steel.

- F593: Generic stainless steel specification used for general purpose applications including anchor rods. Multiple alloy groups and conditions exist within this specification.

- Alloy Group 1: Type 304 stainless steel.

- Alloy Group 2: Type 316 stainless steel.

- A36*: This is a steel round bar specification as opposed to a fastener specification. Engineers should consider specifying F1554 Grade 36 instead of A36 for anchor rods.

- A572*: This is a steel round bar specification as opposed to a fastener specification. Engineers should consider specifying F1554 Grade 55 instead of A572 Grade 50 for anchor rods.

- Grade 50: Anchor rods with a minimum yield strength of 50 ksi.

Configurations

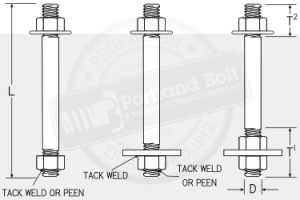

Anchor rods can be manufactured in a variety of configurations, all of which are characterized by a straight rod as opposed to a 90⁰ bent anchor bolt. Anchor rods that are set into a concrete foundation will need a nut, forged bolt head, and/or plate on the embedded end to prevent the anchor rod from pulling out of the concrete. All thread rod and swedged rods are often used with epoxy and installed in preexisting concrete foundations.

Manufacturing

Anchor rods are manufactured by cutting steel round bar to length, applying threads to one or both ends, and sometimes adding labor operations to the embedded end that include forging, swedging, or welding.

Accessories

Anchor rods are supplied with nuts and washers for the projecting end and sometimes for the embedded end. Other accessories include anchor plates, plastic and steel anchor sleeves, and coupling nuts.

- Recommended Nuts and Washers

- Other Accessories

- Plates

- Anchor Sleeves

- Coupling Nuts